Everything about Sacramento Warehouse

Table of ContentsWhat Does Sacramento Crossdock Warehousing Do?The Of Sacramento WarehouseSacramento Cross Dock Fundamentals ExplainedThe smart Trick of Sacramento Crossdock That Nobody is DiscussingSome Of Sacramento Warehouse

As a component of SCM, efficient inventory administration may lead to a more powerful supply chain. Another reason good warehousing is important to SCM is that it provides a method for businesses to make sure the accessibility of the right products at the proper location whenever the time is. It enhances the utility value of the items this way - Crossdock Warehouse.

Of program, they end up being much more reluctant when uncertainty exists around the timely delivery of products. Nowadays, delivery speed appears to be one of the significant aspects that consumers take into consideration when choosing an item and also choosing whether or not to continue with the acquisition.

Sacramento Cross Dock for Dummies

A substantial factor to invest in building a stockroom is the lots of well-known financial advantages that include it. Not only the boosted effectiveness of the supply chain but also the storage facility's storage capability and how it serves as a central location for your products add to its economic advantages.

These things might be seen or become aware through consolidation and also buildup procedures. Right here's a better check out exactly how combination and accumulation can aid lower costs: With consolidation operations, there's no demand to deliver products independently from several sources due to the fact that they might be provided to your storehouse as stocks. When an order is placed, you or your team can load and deliver the item out from there.

Not only that, yet good warehousing additionally enhances customer support and supplies economic advantages. All of these points might lead to greater income and also enhanced business profitability.

Excitement About Sacramento Cross Dock

People who pack items right into a warehouse as well as others ("pickers") that fill up orders in a real circulation facility, plus those who manage the facility as well as procedure. Accessibility to cost-effective transportation to bring items in or relocate them out as orders are met.

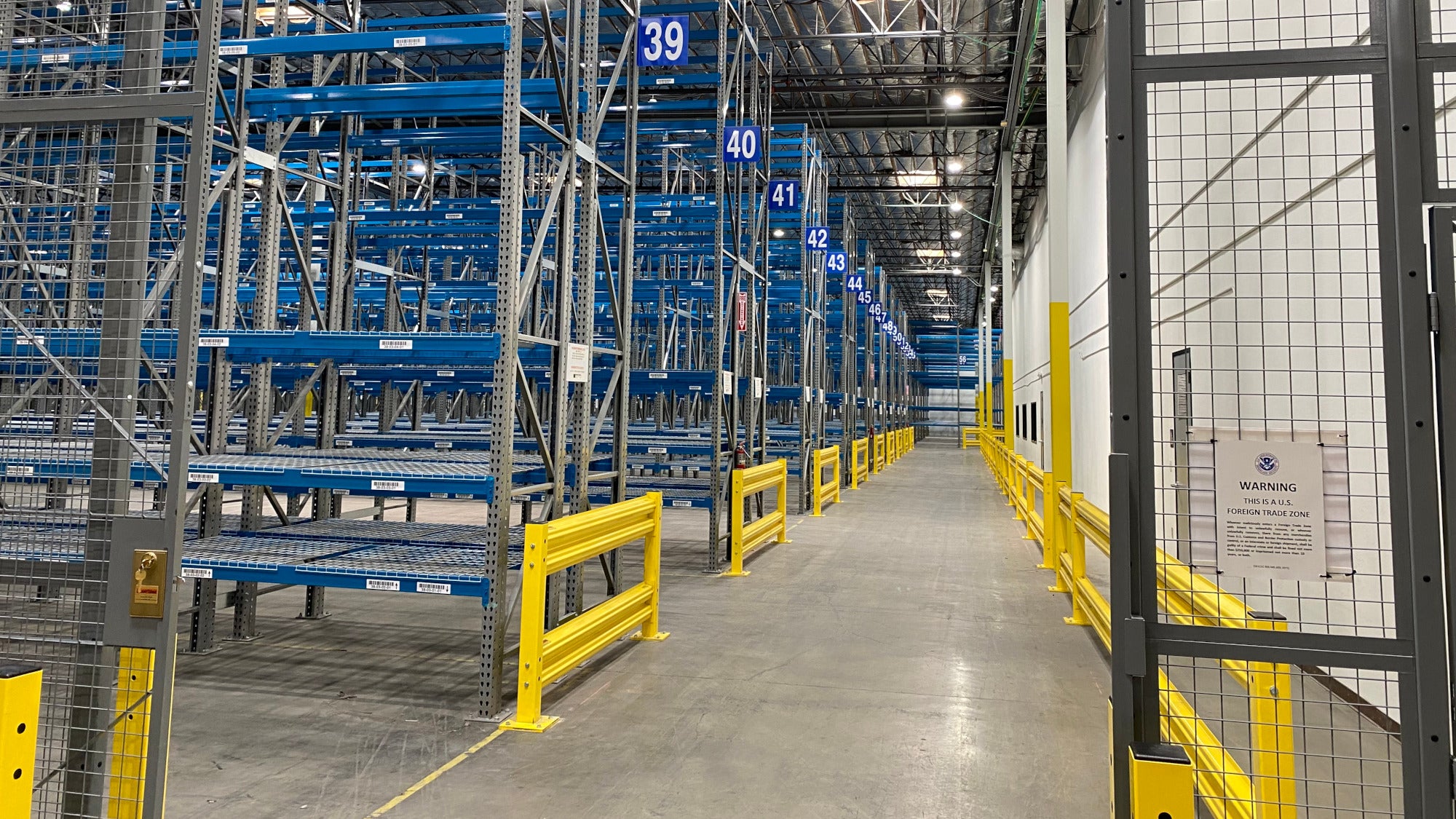

They additionally require to ensure that items are saved in a secure and also safe and secure fashion. Warehouse instances consist of retail shops, distribution centers, cold storage space centers, as well as production plants. In retail shops, things are saved as well as organized in a storage facility as well as shipped to consumers or various other stores. Circulation facilities are utilized to store and also distribute goods to numerous areas.

Warehousing finest technique is to utilize RF Scanners, or similar technologies, to additional enhance supply accuracy and live supply monitoring. Carefully linked with Receiving, Putaway is the last of incoming handling. Putaway is the process of physically, and also systematically, putting items right into their appropriate last storage places (Crossdock Warehouse). Staff chooses Product to putaway from Putaway Hosting area, Typically Pallets or Carts with Product ready to be putaway, Utilizing RF Scanner, determine what cart/pallet/job you are doing away with as well as scan distinct identifier to begin Putaway, Picker travels to location to put product for storage, Ideal best in course systems inform personnel where to put product, but many storehouses still have personnel location product where they recognize there is void (with some standards applied)RF Check Product being putaway as well as Location where the Item is putaway, Continue procedure (go to location and also area supply) up until entire order, pallet, cart, etc is full Weight as well as dimensions of product/pallet being putaway, Stowability of Product (ie breakable, stackable, and so on)Deal volume (best-sellers placed close vs nearby)Amount got, Value of item, Choose Type of Item (solitary pick, batch choice, collection pick, zone choice, and so on) Accurate Putaway is imperative in the storage facility operation, ensuring More Help that Item can be conveniently situated specifically when it is needed.

Top Guidelines Of Crossdock Warehouse

Selecting is the procedure of gathering Products to meet a client's order request. Picker is appointed Choose(s)There are several pick approaches, each operation is special in what is most efficient for their requirements, Area picking, set selecting, single order selecting, wave picking, as well as extra, Using RF Scanner, or comparable, begin selecting by entering the Special Pick Identifier (set #, Order #, SO #, Pick #, other referral)Picker is routed with the Select Path (ideally based on optimization reasoning) to accomplish the Pick, scanning Products as well as Locations as they progress, Chosen things may be positioned in totes, pallets, carts, shelf, etc during pick, Totally chose orders provided to following phase of procedure, Picked orders may be delivered to a High quality Control location, Packing/Shipping area, or directly to outbound staging (if pick to label operation) depending on operation Limitations/abilities of present Stockroom Monitoring System (WMS)Quantity of Orders # of Item Lines browse around these guys per Order, Kind of storage space media (shelving vs racking vs ground pallet storage space)What the Packaging and also Delivery Refine looks like (closely intertwined to Picking)Product require extra interest during packaging? Transport Administration System (TMS) capable of supplying delivery tags before products are chosen?

If during delivering the weight is not within the defined resistance range, after that the user will be motivated to take action, Measurement tolerance check throughout Delivery, Similar to Weight resistance based on system dimension information Packaging as well as Delivery is a major focus of stockrooms, as it commonly becomes a bottleneck given that Order Processing Time need to be as brief as feasible to fulfill consumer expectations.

Do NOT sacrifice top quality! It is vital to keep in mind, depending on the stockroom operation Packaging might be combined with the Choosing procedure. Inventory Control is an important component of all warehouse operations. You can ensure the stock at the stockroom is accurate and updated with a well defined Stock Control procedure.

Sacramento Crossdock Warehousing Can Be Fun For Everyone

Cycle Matters and also Complete Stock Counts are browse around this web-site tools connected with preserving Supply Control. Cycle Matters happen continuously while typical operations continue, but Full Stock Counts take place regularly and also call for all item motion to cease till a complete accurate matter is completed. Shutdown all supply motions, finishing all Product Movements in the Warehouse (literally as well as systematically)Make certain all incoming and outgoing orders that have been literally processed, have actually likewise been processed in WMSBreak storage facility team into teams to matter (occasionally 1 person team okay)Teams are assigned areas to count Assign small-medium areas to count, then groups sign in for more locations as required, Groups count designated areas, taping counts of item per location, Groups commonly utilizing RF Scanners to videotape matters, Otherwise need to do paper-based which is tough to accomplish a Blind Matter, Group reports back once finished and obtain next Count Task, After areas are Counted, the Manager/Lead assesses all Variations, Manager assigns various Team to state the distressed Products and/or Locations, If 2nd group counts like 1st group, make inventory modification to match physical matter.